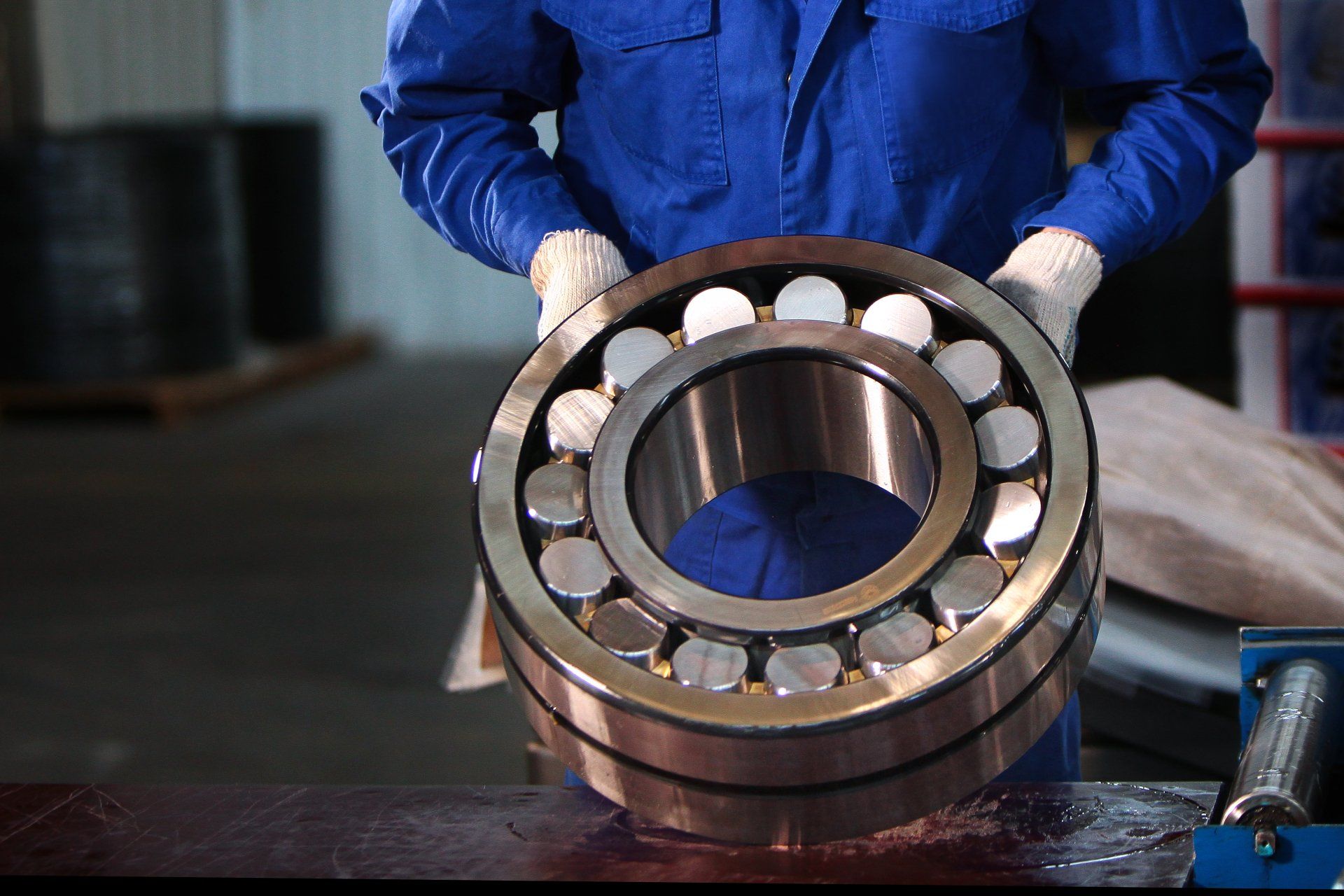

BEARING FAILURE CASE STUDIES

JAD Analysis is independent from any one bearing manufacturer, so you can trust our experts to provide unbiased reports without prejudice.

We have provided reports for the automotive and industrial engineering sectors as well as for aftermarket distributors, these reports have been either simple reviews of photo taken by the end user through more in-depth investigations of failed components returned to our workshop or inspected in statue at your site through to confidential reports prepared under instruction from legal counsel.

Send us your photos of failed or damaged bearings through this website for analysis. Just click through to our contact page, where you will find the facility to attach and upload images alongside a message, for our team to examine. We'll get back to you with our initial thoughts and advise on how best to investigate the damage or failure.

UPLOAD YOUR PHOTO

BEARING FAILURE CASE STUDIES

JAD Analysis is independent from any one bearing manufacturer, so you can trust our experts to provide unbiased reports without prejudice.

We have provided reports for the automotive and industrial engineering sectors as well as for aftermarket distributors, these reports have been either simple reviews of photo taken by the end user through more in-depth investigations of failed components returned to our workshop or inspected in statue at your site through to confidential reports prepared under instruction from legal counsel.

Send us your photos of failed or damaged bearings through this website for analysis. Just click through to our contact page, where you will find the facility to attach and upload images alongside a message, for our team to examine. We'll get back to you with our initial thoughts and advise on how best to investigate the damage or failure.

UPLOAD YOUR PHOTO

Three Levels of Report on Bearing Damage and Failure

Download J A D's latest case studies on this page, giving examples of the three levels of report available. These include.

CLASS A

EXPERT WITNESS

Expert Witness: To be used as part of a claim or court case.

CLASS B

DETAILED ANALYSIS

Detailed Analysis: To be used to analyse bearing failure or damage that has occurred during service.

CLASS C

REMOTE VIEW

Remote Review: To be used to remotely review a failed or damaged bearing, with no requirement to transport the components to J A D.

Contact Us

We will get back to you as soon as possible.

Please try again later.

-

CLASS A - BEARING FAILURE LEGAL REPORT FRAMEWORK EXAMPLE

Revealing the framework of J A D's Class A report (but left blank as these reports are always confidential) a full report in this category will cover multiple pages and include digital images, descriptions of damage and comments on the failure mode identified in accordance with the requirements of part 35 civil procedure rules.

-

CLASS B - BBU CYLINDRICAL ROLLER ELECTRIC MOTOR BEARING FAILURE

A single rhombic ball bearing unit (BBU) plus casting and bearing was supplied to us for inspection and report. We have no information on intended or fitted application. On removal of the outer packaging, the casting and BBU were found. A single hair line crack was seen running through the casting at a point approximately 90 degrees from the centreline of the bolt holes.

-

CLASS B - ELECTRIC MOTOR BEARING FAILURE

Two 6202 deep groove ball bearings retained at the ends of an electric motor shaft were supplied to us for inspection and report. We understand that the bearings have been in service for only three to four months and that there was a complaint that the long shaft bearing was notchy. On the long shaft we understand that there was a steel impeller installed and that the end user acknowledges that this impeller was out of balance during service.

-

CLASS B - PULLEY BEARING FAILURE

Two 6219 ZZC3 shielded deep groove ball bearings and a central shaft from a damaged lift pulley were delivered to our workshop. One of the bearings was in an assembled condition; however, the other had a cracked inner raceway and two loose metal shields. All bearings were very dirty and had a coating of unidentified gummy residue. The gummy residue had a strong rubbery smell.

-

CLASS B - SINGLE CYLINDRICAL ROLLER ELECTRIC MOTOR BEARING FAILURE

A single cylindrical roller bearing was supplied to us for inspection and report. From information provided, we understand that the bearing had been fitted to an electric motor and that the end user required confirmation of the failure mode.

-

CLASS B - TAPERED ROLLER AUTOMOTIVE WHEEL BEARING FAILURE

A wheel bearing was supplied to us for inspection and report, a double row tapered roller hub unit. We understand that the bearing had been fitted to a van with a mileage of 123,095 recorded. We understand that the kit was fitted then failed two days later whilst on a motorway.

-

CLASS B - WIND TURBINE BLADE PITCH BEARING ANALYSIS

Three wind turbine Rotor Pitch Blade bearings that had been in service for approximately 10 and a half years were supplied to us for inspection and report. Rotor pitch blades are adjustable in order that the wind generator turbines can produce maximum output. The bearings that support the blades have to withstand continuous load changes resulting from these pulsating loads.

-

CLASS C - ELECTRIC MOTOR BEARING FAILURE

J A D Associates were asked to review a number of digital photographs taken by Arfon Rewinds to establish a possible cause for the damage that had occurred to a motor being operated by their customer, referred to in this report as "the end user".

-

CLASS A - BEARING FAILURE LEGAL REPORT FRAMEWORK EXAMPLE

Revealing the framework of J A D's Class A report (but left blank as these reports are always confidential) a full report in this category will cover multiple pages and include digital images, descriptions of damage and comments on the failure mode identified in accordance with the requirements of part 35 civil procedure rules.

-

CLASS B - BBU CYLINDRICAL ROLLER ELECTRIC MOTOR BEARING FAILURE

A single rhombic ball bearing unit (BBU) plus casting and bearing was supplied to us for inspection and report. We have no information on intended or fitted application. On removal of the outer packaging, the casting and BBU were found. A single hair line crack was seen running through the casting at a point approximately 90 degrees from the centreline of the bolt holes.

-

CLASS B - ELECTRIC MOTOR BEARING FAILURE

Two 6202 deep groove ball bearings retained at the ends of an electric motor shaft were supplied to us for inspection and report. We understand that the bearings have been in service for only three to four months and that there was a complaint that the long shaft bearing was notchy. On the long shaft we understand that there was a steel impeller installed and that the end user acknowledges that this impeller was out of balance during service.

-

CLASS B - PULLEY BEARING FAILURE

Two 6219 ZZC3 shielded deep groove ball bearings and a central shaft from a damaged lift pulley were delivered to our workshop. One of the bearings was in an assembled condition; however, the other had a cracked inner raceway and two loose metal shields. All bearings were very dirty and had a coating of unidentified gummy residue. The gummy residue had a strong rubbery smell.

-

CLASS B - TAPERED ROLLER AUTOMOTIVE WHEEL BEARING FAILURE

A wheel bearing was supplied to us for inspection and report, a double row tapered roller hub unit. We understand that the bearing had been fitted to a van with a mileage of 123,095 recorded. We understand that the kit was fitted then failed two days later whilst on a motorway.

-

CLASS B - SINGLE CYLINDRICAL ROLLER ELECTRIC MOTOR BEARING FAILURE

A single cylindrical roller bearing was supplied to us for inspection and report. From information provided, we understand that the bearing had been fitted to an electric motor and that the end user required confirmation of the failure mode.

-

CLASS B - WIND TURBINE BLADE PITCH BEARING ANALYSIS

Three wind turbine Rotor Pitch Blade bearings that had been in service for approximately 10 and a half years were supplied to us for inspection and report. Rotor pitch blades are adjustable in order that the wind generator turbines can produce maximum output. The bearings that support the blades have to withstand continuous load changes resulting from these pulsating loads.

-

CLASS C - ELECTRIC MOTOR BEARING FAILURE

J A D Associates were asked to review a number of digital photographs taken by Arfon Rewinds to establish a possible cause for the damage that had occurred to a motor being operated by their customer, referred to in this report as "the end user".

LATEST NEWS

JAD Associates (Improvement Solutions) Limited, Stratford House, 4 Plough Drive, Market Rasen, Lincs, LN8 3DW

© Copyright 2022 JAD Associates Privacy Policy Created by Push Creativity Websites