EXPERT ANALYSIS OF BEARING DAMAGE OR FAILURE

For over 25 years J A D Analysis has carried out investigations and inspections on failed or damaged ball and roller bearings. Our aim is to provide large and small engineering companies, the bearing distribution trade and any user of bearings with a source for straightforward, plain English, reports to assist either in the prevention of future failures or to help in the resolution of bearing performance complaints.

EXPERT ANALYSIS OF BEARING DAMAGE OR FAILURE

For over 25 years J A D Analysis has carried out investigations and inspections on failed or damaged ball and roller bearings. Our aim is to provide large and small engineering companies, the bearing distribution trade and any user of bearings with a source for straightforward, plain English, reports to assist either in the prevention of future failures or to help in the resolution of bearing performance complaints.

Three Levels of Report on Bearing Damage and Failure

Visit our bearing failure case study page for examples of each type of report, aside from the Class A Expert Witness reports which are confidential.

Three Levels of Report on Bearing Damage and Failure

Visit our bearing failure case study page for examples of each type of report, aside from the Class A Expert Witness reports which are confidential.

NEWS AND EVENTS

Keep up to date with all the latest news ON TWITTER

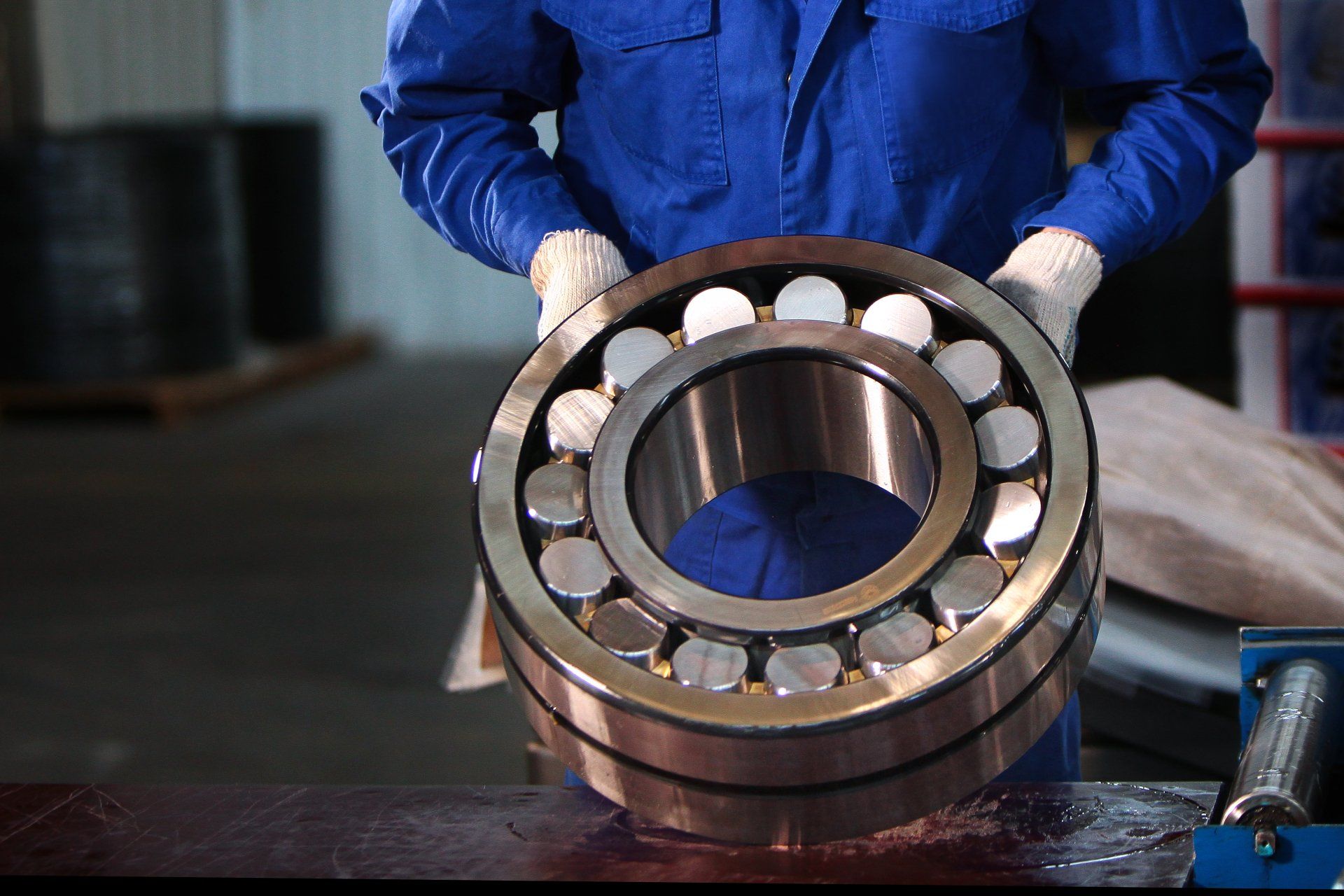

J A D Analysis can perform bearing investigations and bearing failure analysis on most sizes* and types of rolling element bearings.

As a company independent of any one bearing manufacturer, our experts have provided reports for the automotive and industrial engineering sectors as well as for aftermarket distributors. Our reports are unbiased and produced without prejudice.

*Where packages are over 40 KG please contact us in advance to in order that suitable unloading arrangements can be made.

Bearing Failure Inspection and Analysis

Understanding why a bearing has failed is one of the best ways to prevent the same failure from happening again. Almost all bearing failures and damage are either caused by:

All these reasons can be prevented in future once identified.

The team at J A D Analysis has years of experience studying bearing damage and failures that have occurred in automotive, agricultural, general and heavy engineering applications. We extract evidence from the bearing parts and, where available, their mating components; with this evidence we carry out a failure analysis of the application to determine the most likely root cause of the problem.

Improper lubrication

Contamination

Poor installation

Handling or maintenance regimes

FAILure inspection

J A D Analysis provides its customers with a source of straightforward failure analysis reports to assist in the resolution of customer complaints or technical queries. We try to keep our reports on a common sense basis and do not generally resort to complex calculations of stress or metallurgical analysis unless demanded.

Where an end user is claiming compensation for being supplied a 'faulty bearing'

Where a user feels they have been supplied a sub-standard or counterfeit product

Identifying the reasons for a catastrophic bearing failure having occurred

Determining a problem in a machine when the bearings need to be replaced frequently

When a machine or vehicle is stripped for routine maintenance and bearing damage is seen

When selling an improved solution to an existing user

Failure analysis is valuable in situations such as...

The bearing failure experts at J A D Analysis understand that an academic bearing failure study and investigations can be expensive. We therefore utilise our years of experience to identify the problem before any further expense is required.

Failure Analysis

All types of reports from J A D Analysis are easy to understand with, wherever possible, photographic evidence used to demonstrate the points being made. We include a conclusion section that not only highlights the most likely reason for the problem, but also makes recommendations as to how the problem can be prevented in the future.

LATEST NEWS

JAD Associates (Improvement Solutions) Limited, Stratford House, 4 Plough Drive, Market Rasen, Lincs, LN8 3DW

© Copyright 2022 JAD Associates Privacy Policy Created by Push Creativity Websites